Future of End-of-Life Solar PV Panels in Australia

Abstract: In Australia roof-top based solar energy generation is the most popular renewable energy source, since introduction of the feed-in tariff in 2008-09. Because of government incentives, uptake of Solar PV Panels by households and commercial establishments has increased. This growth of Solar PV panels installation has also posed different challenges. Australia is projected to have a cumulative 1 million Tonnes of decommissioned Solar PV panels by 2035, and 80% of this end-of-life Solar PV panels’ volume will generate from Australia’s small-scale residential Solar PV market. However, the new challenge will also provide a new opportunity for the growth of Circular Economy. The new business opportunities will create avenues to invest in processing centers to reuse and recycle Solar PV panels, and that will improve resource recovery from end-of-life Solar PV panels and will also lead to job creation. However, Australia needs a suitable legal framework to promote the Product Stewardship Scheme and in addition, Australia also needs a suitable market structure to reuse and recycle Solar PV panels. Hence, ACSDRI had organized a PODCAST with PAUL BARTLEY to understand the policy agendas relating to reuse and recycle End-of-Life Solar PV Panels in Australia.

Key words: Solar PV Panels, Reuse of Solar PV Panels, Recycling of Solar PV Panels, End-of-Life Solar PV Panels, Product Stewardship

Podcast Topic: Understanding Future of Reuse and Recycling of Solar PV Panels

A Legal & Regularity Perspective

The Podcast addresses SDG - 7, SDG 11, SDG 17, and SDG 13

ACSDRI Podcast: Recycling and Reuse of Solar PV Panels: A Legal Perspective PART 1

ACSDRI Podcast: Recycling and Reuse of Solar PV Panels: A Legal Perspective PART 2

Recoverable Resources and Economic Value of End-of-life Solar PV Panels

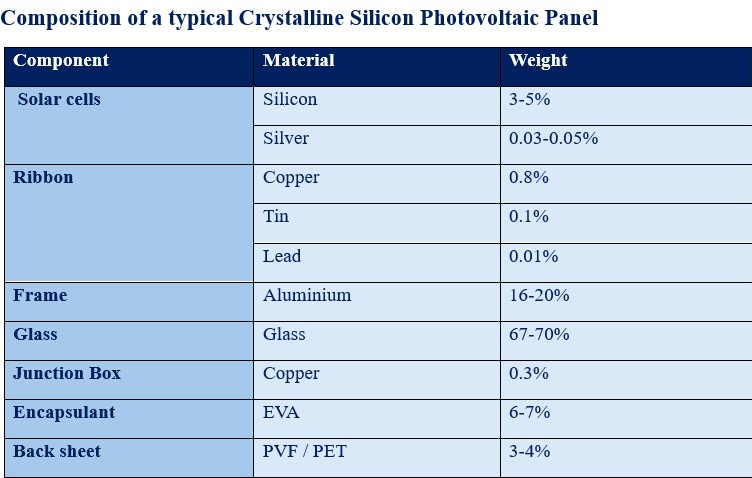

A typical Crystalline Silicon Photovoltaic Panel or household Solar PV Panel weighs about 20 kg. A Solar PV panel is made up of various components and materials, such as Solar cells (Silicon and silver), Ribbon (Copper, Tin, Lead), Frame (Aluminum), Glass, Junction Box (Copper), Encapsulant (EVA), and Back sheet (PVF/PET). Among all materials, glass accounts for about 67-70% of the total weight of Solar PV Panels, whereas other metals such as aluminum account for 16-20% of the weight, silicon for 3-5%, copper for 0.11%, tin for 0.1%, lead for 0.01%, and silver for 0.03-0.05% of the total weight, respectively. From a resource recovery economics point of view, silver has the most recoverable value, followed by tin, copper, silicon, lead, and aluminum respectively. By 2023, the projected value of the total resources recovered from decommissioned Solar PV panels is estimated to exceed 1 billion AUD. At the present market value, a typical 20 kg decommissioned Crystalline Silicon Photovoltaic Panel has potential to recover $22.6 worth of economic resources or over $1000 per tonne of solar PV panels.

Growing volume of End-of-life Solar PV Panels

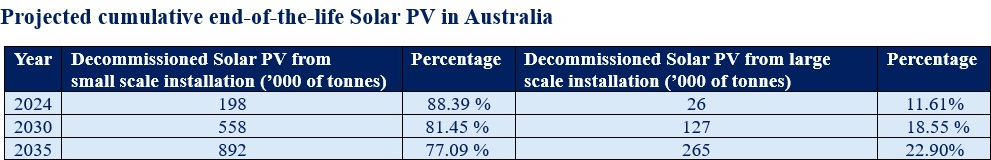

As the world races to reduce CO2 emissions by 2030, the uptake of Solar PV will also grow significantly. This growth of Solar PV installation will pose different challenges. Australia is projected to have a cumulative 1 million tonnes of decommissioned Solar PV by 2035, and 80% of this end-of-life Solar PV volume will be generated from Australia’s small-scale residential Solar PV market. The new challenges will also provide a new Circular Economy based business opportunities to invest in the End-of-Life Solar PV panel’s reuse and recycle processing centers. These new venturers will increase resource recovery business opportunities from end-of-life Solar PV panels, and will also support job creation.

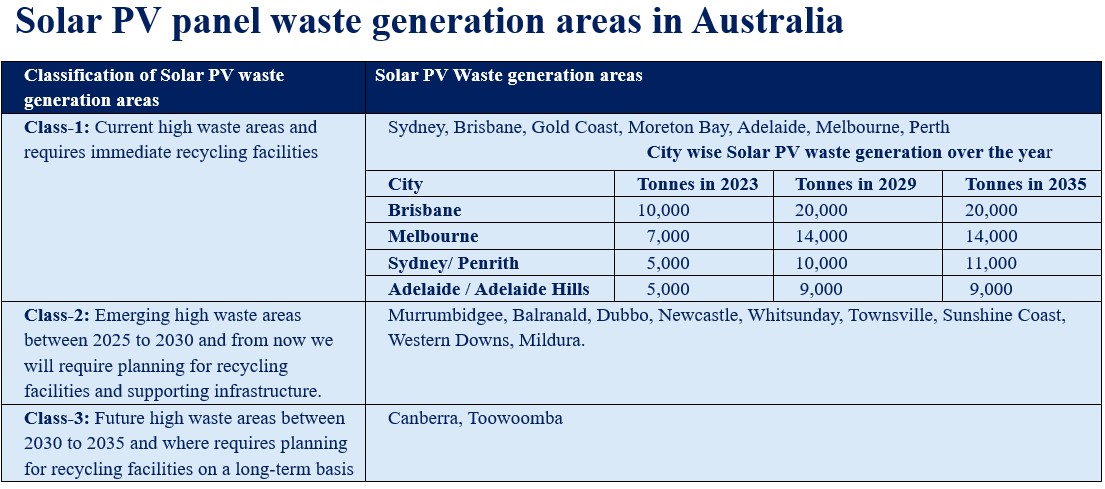

As the cumulative end-of-the-life Solar PV panels’ volumes are increasing, there is an urgent need to invest in recycling facilities. However, the growing volume of decommissioned Solar PV panels are not evenly distributed geographically. The data suggests New South Wales, Victoria, and Queensland will generate the highest proportion of end-of-life Solar panel waste among all Australian states. In addition, all major metropolitan cities like Sydney, Melbourne, Brisbane, Perth, and Adelaide will generate significant volumes of end-of-life Solar Panel waste. There are three-tiered classifications of decommissioned Solar panel waste generation areas in Australia: Class 1, Class 2 and Class 3. Hence investment opportunities in the End-of-Life Solar PV Panels processing centers also guided by these clusters of Solar PV waste generation areas

Economic rationale to reuse and recycle of Solar PV Panels

Regularity landscape to reuse or recycle Solar PV Panels

What is Product Stewardship?

Product stewardship scheme ensures responsible handling of products throughout their lifecycle, including disposal. This encourages industries to reduce environmental and health impacts, promoting sustainable practices. Australia’s national product stewardship scheme for Solar Panels will mandate all parties in the solar market to manage end-of-life Solar PV Panels responsibly. Key aspects include abiding recycling benchmarks, material traceability enforcement, and criteria for recyclers. Globally, the Basel Convention restricts hazardous waste movements for environmentally and socially responsible disposal or recycling. An upcoming amendment in 2025 will prohibit cross-border movement of solar panels, mandating domestic processing and banning export. This amendment aims to boost Australia’s Solar PV Panel based circular economy, will prevent Solar PV Panels from diversion to landfills, and subsidize processing costs through manufacturer fees

Barriers, Opportunities, and Road Map to boost a Circular Economy based on End-of-Life Solar Panels

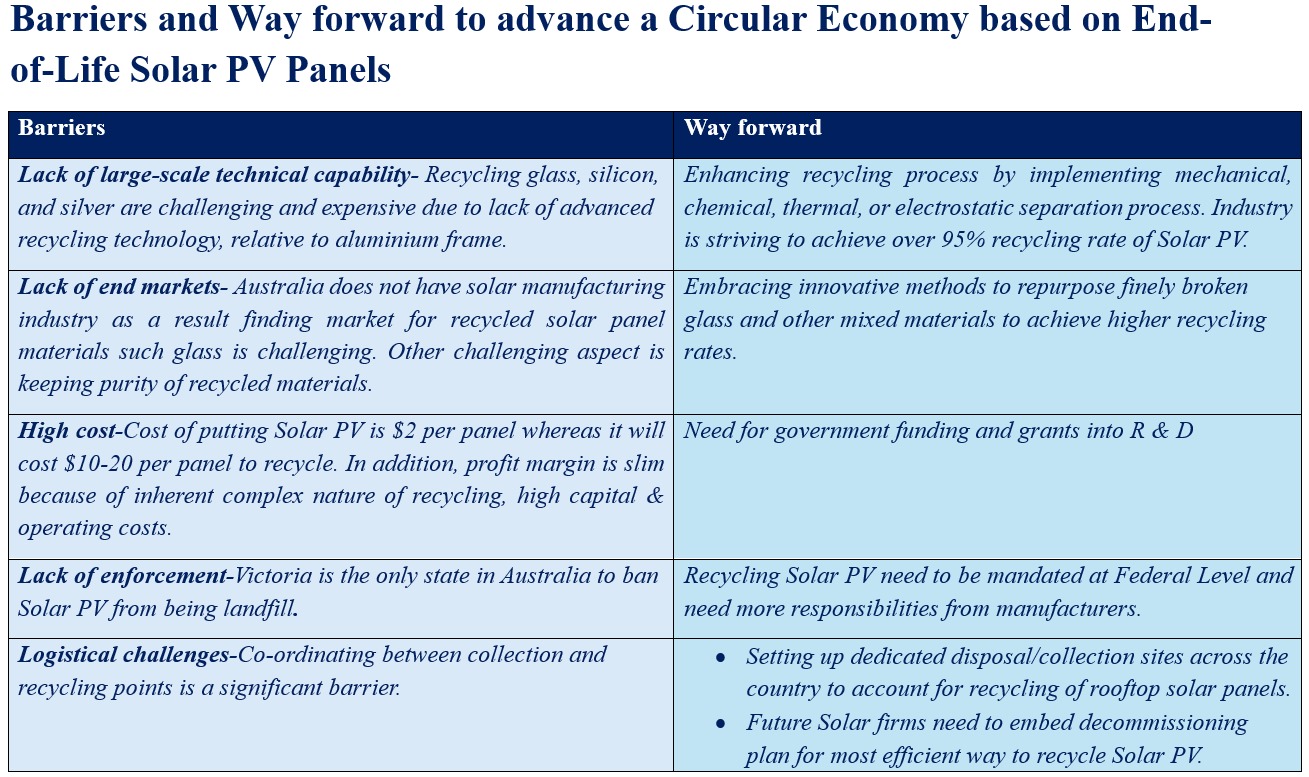

One of the key objectives of Circular Economy is to recover material from any end-of-life product at its high-purity condition. In the case of end-of-life Solar PV Panels, recovering aluminum from the frame is straightforward. However, recovering silver, silicon, and copper at its high-purity level is costly as they are intertwined with other components in small quantities.

Recovering precious minerals requires the application of advanced refining treatments:

- Pyrometallurgical,

- Hydrometallurgical, and

- Electrochemical techniques.

Reuse of Solar PV Panel involves inspection, repair (if it is a repairable part or component such as junction box, cables, back sheet, mounting clamps, bypass diodes), testing, and recertification for safety and performance. If there are non-repairable defects such as broken glass, defective frame, or significant edge delamination, then they should be separated for recycling.

Recycling of decommissioned Solar PV panels can be done in three broad ways:

Road Map to boost a Circular Economy based on End-of-Life Solar PV Panels

Key points discussed with Paul Bratley in the Podcast

- What is Paul’s motivation to peruse his PhD in this topic area?

…In the past Paul had experienced the adverse effects of the externalities of heavy industries (chemical and steel factories) in his neighborhood. In addition to that, he is also concerned about the potential adverse externalities of End-of-Life Solar Panels. Generally, a panel can last 25 to 30 years; however, due to many factors, a panel can have to be replaced within 5 to 10 years for several reasons such as mal-function of panels, panels are damaged due to hail-storm, change of standards, the introduction of more efficient solar panels…Sometimes simply replacing one broken panel with another is also not possible because of a mismatch due to technological changes, which can result in safety issues. At the same time, replacing a damaged solar panel with a similar but recycled solar panel can also have some issues in terms of safety, insurance cover, and legality if the recycled solar panel is not certified or non-compliant. A re-useable solar panel will be obsolete if it is non-compliant…These issues motivated Paul to peruse his PhD research on the regulatory aspect of reusing solar panels…

- Technological issues in recycling Solar panels

…One of the issues raised by Paul is that in some cases, the cost of extracting precious minerals is more than their resell value; there are scopes for technological innovation to bring down the cost of recovering precious minerals from decommissioned Solar PV panels……Implementing a law relating to product stewardship is necessary to promote reuse and recycle Solar PV Panels…

…We can learn from the Tyre industry, where a small percentage is included in the price of a new tyres to fund research on recycling old tyres. Similarly, a percentage can be included in the price of new solar panels that can be set aside to fund Solar Panel decommissioning cost…

…As of now, Product stewardship is still a voluntary responsibility in Australia. We need to learn from the product stewardship program of batteries and soft plastic…Presently, the right-to-repair aspect is embedded in Australian Consumer Law. However, there is no insurance cover when someone is reusing old Solar PVs…Upcoming regulation prohibiting the export of end-of-life Solar PVs…Because of this upcoming law, Australia will see the growth of the Solar panel reuse and recycling business. There is also a scope for introducing a Solar PV Panel decommissioning fee…Since the economic viability of the reuse and recycling Solar PV business is less, there is a scope for adopting a monopoly-based market structure in the Solar Panel reuse and recycling market. In this case, adopting a monopoly-based market structure will be in the public interest…